Can lubricant waste be regulated?

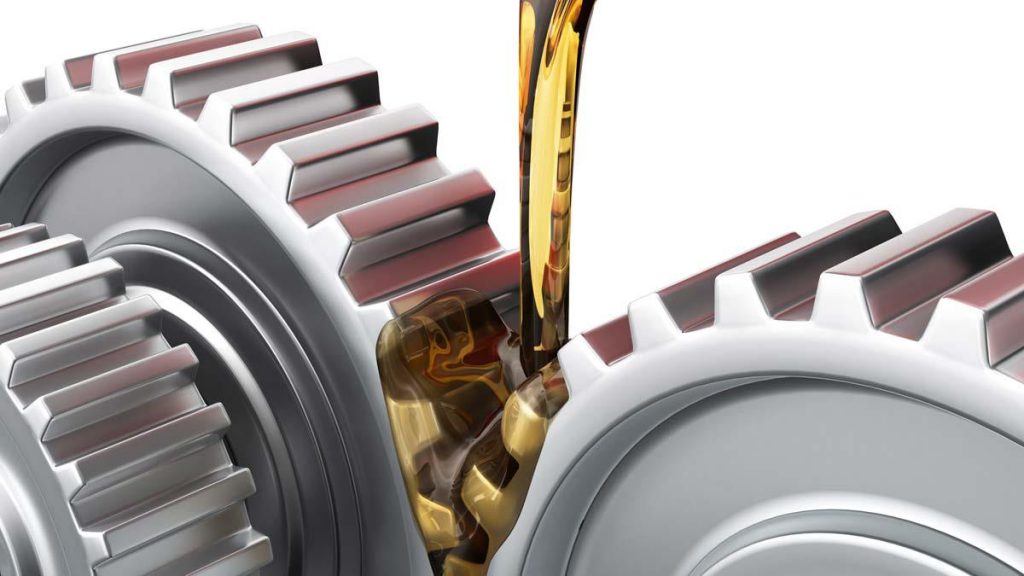

Lubrication is mainly believed to make parts of a machine “slippery”.

In reality, they are substances which play a major role in the bearing and longevity of machinery by;

- Reducing wear of moving parts

- Reducing friction between rotating and stationary parts

- Absorbing shock

- Reducing operating temperatures

- Minimizing corrosion of metal surfaces

- Keeping contaminants out of the system

- Sealing and protecting components.

However, lubricants will need to be replaced from time to time. Contaminants may build up within the lubricant itself or may simply need to be changed, resulting in the creation of lubricant waste.

But then, what happens when the lubricant waste is in excess.

Can lubricant waste be regulated?

Yes, lubricant waste can be regulated.

With Smartflow’s range of Graco Lubrication Management System, you can manage your oils and greases inventory, dispense more intelligently, take control of your expenses and account for every drop.

It helps you improve your operational efficiencies by giving you the ability to;

- Monitor every drop, every time — automatically

- Track issues to the source

- Capture data, integrate with popular DMSs and share data with key stakeholders quickly

- Monitor fluid inventory and schedule refills to minimize delays and excessive costs.

If you’re overseeing a vehicle service centre for cars, trucks or even heavy-duty equipment; it is essential you get our lubrication management system.

Our Graco’s range of lubrication management system leads the industry with wire-free and PC based solution.

With your system in place, you’ll always have the information you need to plan and schedule the deployment of the right amount of lubrication to oil and grease lubricated machinery at the right time.

Speak with our team today to get advice on proper waste lubricant management methods, including how to remove and dispose waste lubricant safely.

Stay ahead of your competition and save more!

Write a Comment

You must be logged in to post a comment.